HAAS CNC Mill Restoration Update

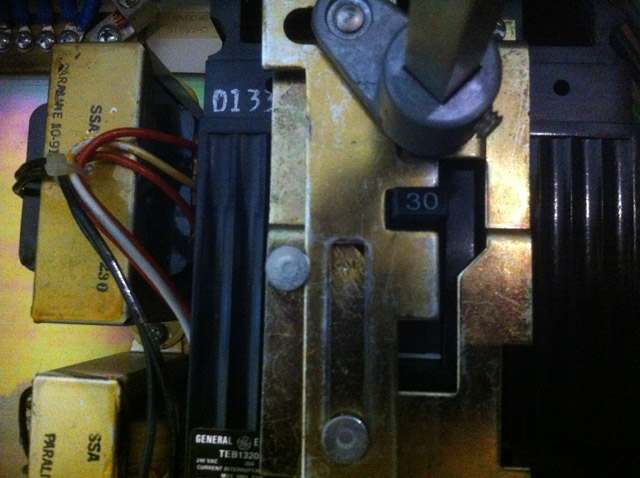

Worked on the Haas this weekend with some goals in mind.1) Fix the switch2) Establish Serial communication3) Receive serial data from mill4) Send serial data to mill5) Execute simple gcode6) After all the above is completed - start cleaning more1) First arriving at the lab, I couldn't turn the switch on the back of the Haas off so I could not open the door. It took three of us (Thanks Ted and Scott) to finally get the door opened. Found the rod that activates the breaker switch was pretty twisted up. Took it off heated it up and peined it back to shape. Re-installed the shaft and found the breaker switch tab was broken off. This was a whole story, but needless to say it's fixed and that's awesome.Second round of heating up the switch shaft, it's almost straight here. Just a little more peining and it'll be great again. The switch all finished.

The switch all finished. 2) Establishing serial connection was needed to be done so we can test the machine further. Major propps go to , Ted, Mike B, Tom for their help. This was my third attempt at serial connection to the Haas, and I wasn't giving up till it was a success. I tried many configurations and nothing seemed to work. I finally put an oscilliscope on the serial out of the haas to see if the signal went high when a send command was issued. This technique worked and I proceeded with this method all the way down the chain (db25>9 adapter, two db9 cables, usb>serial adapter).3) After the above was completed, it was time again to test sending data from the haas. Nothing worked. RRRGGGHH. I did more net searches and found yet another pin configuration to try. I reversed pins 2>3 3>2 with a null modem adapter to 2>2 3>3 and it WORKED!!!! When the data started streaming into my serial sniffer, I was like Tom Hanks in the movie Cast-Away, jumping up and down shouting "FIRE", "I Made Fire!"4) Sending data to the Haas is another small feat as the Haas format is very specific in what the machine considers good code. When receiving unusable code the haas doesn't display an error, it just sits there and does nothing. This made troubleshooting a matter of hit or miss. I tried to resend the gcode data the haas sent to the pc, back to the haas, and it didn't even like it's own code. After some more net searches I found a few things to look for, tweaked my test gcode and the haas received it and logged it into it's program list. WOOT!5) I deleted any motor and spindle commands from the test gcode. (we don't have a toolholder and the air wasn't hooked up). It's a simple 2.5 axis circle cut.FamiLAB's Haas VF-1 starting to come to life.http://www.youtube.com/watch?v=uVdlToumVTcThis is so AWESOME!!! We can further test, clean and reassemble the Haas. Soon we'll be cutting Aluminum 3D Printer frames, rocket parts, and what whatever you could imagine.6) After I came down from the initial high of seeing the Haas moving by gcode program, it was back onto cleaning. I brought in some parts cleaner (mineral spirits). Daniel, thanks for the gloves because the metal chips are real sharp, and the shower curtain to keep the gunk off the machine.Tool-Changer before.

2) Establishing serial connection was needed to be done so we can test the machine further. Major propps go to , Ted, Mike B, Tom for their help. This was my third attempt at serial connection to the Haas, and I wasn't giving up till it was a success. I tried many configurations and nothing seemed to work. I finally put an oscilliscope on the serial out of the haas to see if the signal went high when a send command was issued. This technique worked and I proceeded with this method all the way down the chain (db25>9 adapter, two db9 cables, usb>serial adapter).3) After the above was completed, it was time again to test sending data from the haas. Nothing worked. RRRGGGHH. I did more net searches and found yet another pin configuration to try. I reversed pins 2>3 3>2 with a null modem adapter to 2>2 3>3 and it WORKED!!!! When the data started streaming into my serial sniffer, I was like Tom Hanks in the movie Cast-Away, jumping up and down shouting "FIRE", "I Made Fire!"4) Sending data to the Haas is another small feat as the Haas format is very specific in what the machine considers good code. When receiving unusable code the haas doesn't display an error, it just sits there and does nothing. This made troubleshooting a matter of hit or miss. I tried to resend the gcode data the haas sent to the pc, back to the haas, and it didn't even like it's own code. After some more net searches I found a few things to look for, tweaked my test gcode and the haas received it and logged it into it's program list. WOOT!5) I deleted any motor and spindle commands from the test gcode. (we don't have a toolholder and the air wasn't hooked up). It's a simple 2.5 axis circle cut.FamiLAB's Haas VF-1 starting to come to life.http://www.youtube.com/watch?v=uVdlToumVTcThis is so AWESOME!!! We can further test, clean and reassemble the Haas. Soon we'll be cutting Aluminum 3D Printer frames, rocket parts, and what whatever you could imagine.6) After I came down from the initial high of seeing the Haas moving by gcode program, it was back onto cleaning. I brought in some parts cleaner (mineral spirits). Daniel, thanks for the gloves because the metal chips are real sharp, and the shower curtain to keep the gunk off the machine.Tool-Changer before. Tool-Changer shroud after.

Tool-Changer shroud after. That about wraps it up for now, We could use some help on cleaning and re-assembly. If you could help out please let me know, and thanks in advance.

That about wraps it up for now, We could use some help on cleaning and re-assembly. If you could help out please let me know, and thanks in advance.